Best Pocket Knife Steel in the UK – A Buyer's Guide

Posted by Harley on 7th Sep 2025

At Arctic Knife, we are passionate about folding knives, not just for their craftsmanship and design, but for the fascinating world of metallurgy that underpins them. One brand that has done more than most to fuel this fascination is Spyderco. Their willingness to experiment with new and often exotic steels has made them a pioneer in the industry and a favourite among collectors. From introducing everyday users to steels like HAP40 and REX121, to being among the first to bring MagnaMax to production knives, Spyderco has given enthusiasts across the UK the chance to experience cutting-edge metallurgy in their pockets.

If you are searching for the best pocket knife steel in the UK, you have likely seen names such as S30V, S45VN, SPY27, VG-10, M398, S110V, S90V, M390, MagnaCut, , CRUWEAR, Maxamet and many more. It can be overwhelming to know where to start.

For many enthusiasts, part of the thrill of collecting folding knives is experiencing these steels firsthand, seeing where they shine, where they falter, and how they feel in day-to-day use. But for newcomers, and even seasoned knife users, it can be confusing. How do you know which steel is right for you?

This quick guide will equip you with the key considerations for choosing the right blade steel for your folding pocket knife.

Why Blade Steel Matters

The steel is the heart of the knife. While blade shape, handle ergonomics and locking mechanisms all play their part, the performance of your knife ultimately comes down to the material it is made from. Interestingly, very few steels were originally designed specifically for knives. The majority of the steels we prize today, were first developed for industrial tools.

Knife makers select and heat-treat these steels to bring out their best qualities for cutting tasks. But no steel is perfect. Every single one is a compromise, a balance of traits that must be weighed based on how you intend to use your knife.

The Big Three: Edge Retention, Toughness and Corrosion Resistance

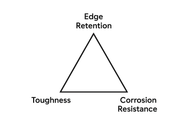

When it comes to selecting the best folding pocket knife steel, there are many performance metrics to consider but for today, we'll focus on these three primary traits, The Big 3:

-

Edge Retention – How long does the blade stay sharp during use?

-

Toughness – How well does the blade resist chipping or snapping under stress?

-

Corrosion Resistance – How well does the blade resist rust and staining?

Imagine these three traits as the points of a triangle. Each steel sits somewhere within that triangle. A steel like M390 lies near the centre, offering a good balance of all three. Maxamet, on the other hand, is far toward the edge retention point, razor-sharp for absolutely ages, but relatively brittle. CPM-4V sits close to the toughness point, able to take abuse without chipping but requiring more frequent sharpening and care against rust.

The key takeaway is that you cannot push one trait to the extreme without pulling away from the others.

Edge Retention: The Long Cutting Champion

Edge retention is often the most talked-about property, and for good reason. A knife that stays sharp longer is incredibly convenient. Steels like Maxamet, S110V and REX 121 excel here thanks to their high hardness and high vanadium carbide content. But this comes at a price, as these steels can be challenging to sharpen and most importantly, may chip under hard use.

For example, Spyderco has produced several models in Maxamet steel, such as their Para 3 and Para Military 2, which delivers exceptional slicing performance for extended periods with minimal maintenance, provided you use it on clean, predictable materials.

Toughness: For the Hard Knock Life

If you use your knife for rougher tasks, cutting dirty materials, wood processing or outdoor survival, you may value toughness more than edge retention. CPM CRUWEAR, (a personal favourite), is a prime example, as it resists chipping and breaking far better than most high hardness steels. The trade-off is that you will sharpen it more often.

Corrosion Resistance: Fighting the Elements

For those who work around water, humidity or maritime environments, corrosion resistance is critical. Steels like H2 sacrifice edge retention to achieve near immunity to rust, while LC200N (originally designed for NASA’s ball bearings in space) strikes a superb balance of corrosion resistance while retaining great edge performance. Spyderco’s SpydieChef is a well-known model using LC200N a favoured knife by food preppers, while steels like H2 found in the Atlantic and Pacific are favoured by sailors, fisherman, watersports enthusiasts, divers and outdoor adventurers alike.

Balanced Steels: The Everyday Heroes

For most users, a well-balanced steel is the sweet spot. Steels like S30V, S45VN, SPY27 and M390 offer an excellent mix of performance traits without demanding constant maintenance or delicate handling.

Then there is CPM MagnaCut, a game changer in modern metallurgy. Designed specifically for knives by Dr Larrin Thomas, MagnaCut challenges the traditional trade-offs, delivering impressive edge retention alongside truly levels of outstanding corrosion resistance and toughness. It is no wonder we are seeing it everywhere, and Spyderco has already released several popular SALT models using this steel.

Other Factors to Consider

-

Sharpenability – Highly wear-resistant steels were once a chore to sharpen, but with modern guided sharpening systems and diamond or CBN abrasives, this is less of a concern for many knife enthusiasts.

-

Your Cutting Environment – Are you at sea, in the workshop, or on the trail? The materials you cut and the conditions you face should guide your steel choice.

-

Task Specialisation – Owning more than one knife is encouraged, each optimised for a different role. A hard, high edge-retention steel for light cutting tasks, and a tough, corrosion-resistant steel for the rough stuff.

Asking the Right Questions

Before selecting a knife, ask yourself:

-

How often am I willing to sharpen?

-

Do I need rust resistance above all else?

-

Will my knife see hard, dirty work or mostly clean slicing?

-

Am I looking for an all-rounder or a specialist?

Your answers will naturally lead you to the right part of the triangle.

Final Thoughts

The world of knife steels is deep, complex and endlessly fascinating. Whether you are chasing the cutting-edge performance of exotic tool steels or sticking to tried and true balanced options, the key is to match the steel to your real-world needs.

And remember, there is no “best” steel, only the right steel for the job.

If you would like to dig deeper, we highly recommend KnifeSteelNerds.com, a treasure trove of steel science.

And of course, our team at Arctic Knife is always here to help you find your next favourite folder, reach out today with any and all questions on steel. You'll wish you never asked.